WHAT IS A LAB CREATED DIAMOND?

The number one question we get is “Are lab-created diamonds real diamonds?” (also called man-made diamonds or lab-grown diamonds)

The answer is a very simple yes.

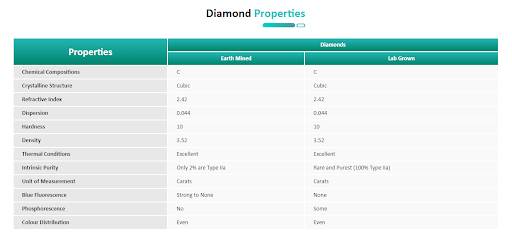

The only thing that makes a lab-created diamond different from a natural diamond is its origin. A lab-created diamond is “grown” inside a lab using cutting-edge technology that replicates the natural diamond growing process. The result is a man-made diamond that is chemically, physically, and optically the same as those grown beneath the Earth’s surface.

“[Lab-created diamonds] are not fakes. They’re not cubic zirconias. They have all the same physical and chemical properties of a mined diamond.” Stephen Morisseau, a spokesman for the Gemological Institute of America, a nonprofit organization that oversees the international diamond grading system.

Sometimes, lab-created diamonds are referred to as synthetic diamonds. While not technically inaccurate, term “synthetic” may be the reason people believe lab-created diamonds are “fake.”

If we compare them to other popular diamond simulants, it’s obvious that manufactured diamonds, in fact, the real deal.

BENEFITS OF LAB-CREATED DIAMONDS

Eco Friendly

For every carat of diamond that is mined, nearly 100 sq ft of land is disturbed and almost 6000 lbs of mineral waste is created.

Ethically Sourced

All in all, mined diamonds result in 1 injury for every 1,000 workers annually, while lab-grown diamonds result in zero.

Competitively Priced

No diamond is free, but due to the shorter supply chain, lab-grown diamonds can be anywhere from 20-30% less expensive than mined diamonds.

HOW ARE LAB-CREATED DIAMONDS GROWN?

Before we talk about how lab-created diamonds are made, it’s important to understand how mined diamonds are formed. The processes are extremely similar - only one happens naturally while the other occurs in a lab

Mined Diamonds Geologists believe that diamonds formed deep within the Earth between 1 billion to 3 billion years ago. While they don’t know exactly how those diamonds came to be, they believe the process starts with carbon dioxide that is buried roughly 100 miles beneath the Earth’s surface.

The carbon dioxide is exposed to heat in excess of 2,200 degrees Fahrenheit and put under extreme pressure of roughly 727,000 pounds per square inch. The diamonds are then transported from deep within the Earth’s core to the surface by way of deep volcanic explosions.

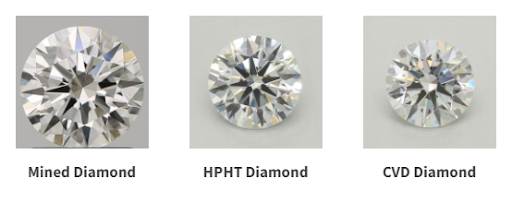

Lab-created Diamonds There are two processes labs use to grow diamonds - High Pressure-High Temperature (HPHT) and Chemical Vapor Deposition (CVD).

HPHT diamonds are made using one of three manufacturing process: a belt press, the cubic press, and the split-sphere (BARS) press. All of these processes create an environment of extremely high pressure and temperature conducive to diamond growth.

An HPHT diamond begins as a small diamond seed that is placed into carbon. Using one of the manufacturing processes above, the seed is exposed to temperatures of about 1500 degrees Celsius and pressurized to approximately 1.5 million pounds per square inch.

The pure carbon melts and starts to form a diamond around the starter seed. It is then carefully cooled to form a pure carbon diamond.

A CVD diamond begins as a thin slice of diamond seed, which is often an HPHT produced diamond. The diamond seed is placed in a sealed chamber and heated to around 800 degrees Celsius.

The chamber is filled with a carbon rich-gas, like Methane, and other gases. The gases are ionized into plasma using technology similar to that of microwaves or lasers. The ionization breaks the molecular bonds in the gases, and the pure carbon adheres to the diamond seed and slowly crystallizes.

HOW ARE LAB-CREATED DIAMONDS CERTIFIED AND GRADED?

Lab-created diamonds are graded and certified using the same process as mined diamonds.

Diamonds are sent to a gem lab that specializes in grading diamonds. The majority of these labs grade using the 4c’s (cut, clarity, color, and carat — more on those later), however, a select few use their own criteria.

The most popular diamond certification labs are:

Gemological Institute of America (GIA)

Antwerp World Diamond Center (AWDC)

American Gem Society (AGS)

International Gemological Institute (IGI)

The diamond grading process is roughly the same for all of the diamond certification labs. Each diamond is graded independently by several gemologists at the lab. The individual grades are compiled and analyzed to determine the final grade.

This process is designed to provide each diamond with an unbiased grade. However, it’s not uncommon for a diamond to get a different grade, not only from a different lab but from the same lab if sent back for a second grading.

For this reason, there are a lot of differing opinions amongst consumers and diamond retailers as to which lab is the “best.” But, it’s important to keep in mind that those opinions are completely subjective. Each lab, much like anything in life, has its pros and cons.

A diamond retailer chooses which lab they use because they trust that lab to grade diamonds fairly. If diamond certification is an important factor in your purchase, you should have a candid conversation with your jeweler about which lab they use and why.

More than anything, jewelers want you to be confident in your purchase, so don’t be afraid to ask questions in order to find the best lab-created diamonds for your engagement ring or jewelry.

A diamond is evaluated using the 4c’s - cut, clarity, color, and carat. Basically, they judge the diamond on how well it has been cut down from its raw form into a jewel, how flawless and clear it is, and its size.

Grown diamonds are made one of two ways - either through High-Pressure High-Temperature (HPHT), or through Chemical Vapor Deposition (CVD).

HPHT recreates the natural growing environment found within the earth. There are a few different types of HPHT technologies used, but the process best suited for producing gem quality diamonds to be set in finished jewelry are created using a Bar press. The Bar press was invented by Russian scientists and uses a combination of inner and outer anvils to apply hydraulic pressure to the growth cell within the unit. The growth cell itself contains all the elements necessary to grow a diamond, including a tiny diamond seed, highly refined graphite and a catalyst consisting of a mixture of metals and powders. Consistent temperatures reaching 1,300 degrees Celsius and over 50,000 atmospheres of pressure are applied to the growth cell. Over a few days the elements within the growth cell melt and then reform during cooling to create a finished rough diamond ready to be extracted for cutting and polishing.

Scientists start the process of growing diamond by cutting a small piece of carbon, known as a seed. It is placed in a low-pressure microwave chemical vapor deposition (CVD) chamber. Gases combine with electrical energy, which ignites a plasma ball. From there a cloud forms in the chamber and carbon molecules rain on the seed. Within six to 12 weeks, a sizeable rough diamond is formed. It is then cut, polished and graded by the same world-renowned labs that certify earth-mined diamonds.